Edm Setup | Erodex

About Business

Optimizing Precision Machining with Erodex Wire EDM Setup

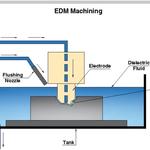

In precision machining, the efficiency and accuracy of wire EDM (Electrical Discharge Machining) setups are crucial for achieving outstanding results. Erodex, a leader in the industry, provides cutting-edge solutions that enable manufacturers to elevate their precision machining capabilities.

Key Elements of Wire EDM Setup

Erodex Wire EDM setups are engineered to meet the high standards of contemporary manufacturing. The process begins with the selection of premium materials, ensuring durability and longevity. The wire, often crafted from brass or coated with a specialized conductive layer, is chosen for its excellent conductivity and wear resistance.

Precision Calibration

Central to any EDM setup is precision calibration. Erodex utilizes advanced calibration techniques to fine-tune machines for optimal performance. This ensures minimal wire deflection, reducing the risk of dimensional deviations during machining. Such meticulous calibration underscores Erodex’s commitment to industry excellence.

Automated Tension Control

Erodex Wire EDM setups feature automated tension control systems, a vital innovation that ensures consistent machining quality. This technology dynamically adjusts wire tension throughout the machining process, compensating for any variations that may occur. The result is enhanced precision and an extended wire lifespan, minimizing downtime for replacements.

Advanced Power Supplies

The power supply is a critical element in Wire EDM, affecting both material removal rates and surface finishes. Erodex incorporates state-of-the-art power supply technology that allows precise control of electrical discharges. This capability ensures optimal machining speed while maintaining high precision, meeting the rigorous demands of modern manufacturing.

Integrated Filtration Systems

To sustain EDM performance, maintaining clean dielectric fluid is essential. Erodex Wire EDM setups include integrated filtration systems that efficiently remove debris and contaminants from the dielectric fluid. This not only boosts machining accuracy by preventing workpiece contamination but also prolongs the lifespan of machine components.

In the quest for excellence in precision machining, Erodex Wire EDM Setups exemplify technological sophistication. From precise calibration to automated tension control and advanced power supplies, every aspect of Erodex’s offerings is meticulously crafted to enhance machining standards. Manufacturers choosing Erodex can trust in achieving unmatched precision, efficiency, and reliability in their EDM processes.

Keywords

Other Businesses

Acoustic Engineers & Services

ValcousticsCanadaLtd

Acoustic Engineers & Services

Eaxprts

Acoustic Engineers & Services

Albe Engineering

Acoustic Engineers & Services

Reliability Maintenance Solutions Ltd

Acoustic Engineers & Services

Gill Electrical and Gas

Acoustic Engineers & Services

DrunkLab

Acoustic Engineers & Services

Maintech Engineering & Supplies

Acoustic Engineers & Services